化工反应釜搅拌机目前的选型方法多数是根据实践经验,选择习惯应用的桨型,再在常用范围内决定搅拌器的各种参数。也有通过小型试验,取得数据,进行比拟放大的设计方法,因此反应釜的选型不是绝对的,前提是保证搅拌的效果。

化工反应釜搅拌机目前的选型方法多数是根据实践经验,选择习惯应用的桨型,再在常用范围内决定搅拌器的各种参数。也有通过小型试验,取得数据,进行比拟放大的设计方法,因此反应釜的选型不是绝对的,前提是保证搅拌的效果。不论哪种做法,都离不开最初的根据搅拌目的来选择反应釜搅拌器类型这一步。所以一个完整拌目的来选择反应釜搅拌器类型这一步。所以一个完整的选型方案必须满足经济与安全的要求,根据具体工况最后确定最佳方案。

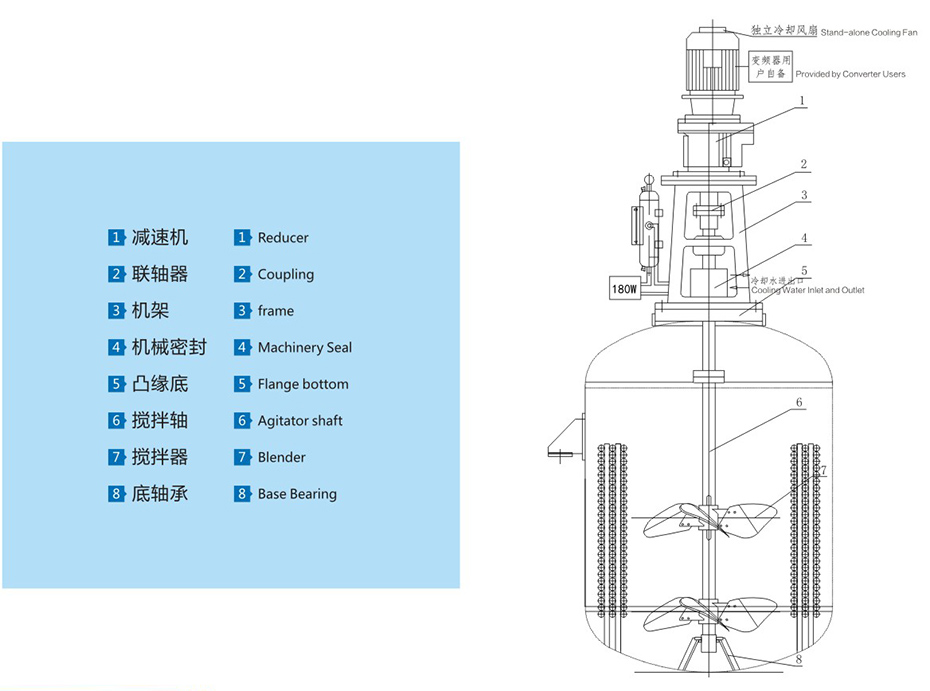

1、按反应釜桨叶搅拌结构分为平叶、斜(折)叶、弯叶、螺旋面叶式搅拌器。桨式、涡轮式搅拌器都有平叶和斜叶结构;推进式、螺杆式和螺带式的桨叶为螺旋面叶结构。根据安装要求又可分为整体式和剖分式,便于把搅拌器直接固定在搅拌轴.上而不用拆除联轴器等其他部件。

2、按反应釜搅拌器的用途分为低黏流体用搅拌器、高黏流体用搅拌器。用于低黏流体的搅拌器有:推进式、桨式、三叶后完式等。用于高黏流体的搅拌器有:锚式、框式、锯齿圆盘式、螺旋桨式、螺带式等。

3、除此之外,化工反应釜对于密封则也是相当严格的,有常规单端面机封,双端面机封,填料密封,根据不同的场合选择合适的密封方式才是最佳选型。

Most of the current selection methods of the reactor agitator are based on practical experience, selecting the paddle type that is customarily applied, and then determining various parameters of the agitator within the usual range. There are also design methods that use small experiments to obtain data and perform comparative amplification.Therefore, the selection of the reactor is not absolute, provided that the stirring effect is ensured. Either way, the initial step of selecting the type of reactor stirrer based on the purpose of mixing is indispensable.Therefore, a complete selection plan must meet economic and safety requirements, and finalize the best solution according to the specific working conditions.

1. According to the mixing structures of reactor blades, the mixers are divided into flat-blade, in dined (folded)-blade, curved-blade and helicoids-blade mixtures. Paddle and turbine mixers have flat-blade and inclined-blade structures. Impeller-type, crew-type and spiral ribbon-type blades are a helicoids-blade structure. According to installation requirements, mixers can be divided into an integral type and a split type so that it is easy to be directly fastened on the mixing shaft and doesn't need to disma ntle other parts in cludi ng couplings.

2. According to purposes of reactor mixers, they can be divided into mixers for low-viscosity fluids and mixers for high-viscosity fluids. The mixers for low-viscosity fluids in elude impeller-type, blade-type, open turbine-type, disc turbine-type, Brumagin-type, plate and frame blade-type and three-backward bent type mixers. The mixers for high-viscosity fluids in elude an chor-type, frame-type, jagged disc-type, propeller-type and spiral ribbon-type mixers.

3. In addition, chemical reactors have a strict requirement of sealing.There are general single-end face mechanical seals, double-end face mechanical seals and packing seals. It is the best model selection to choose a proper sealing method according to different scenarios.

适用于石油、化工、医约、冶金、科研、大专院校等部门进行高温、高压的化学反应试验,用来完成水解、中和、结晶、蒸懈、蒸发、储存、氢化、炷化、聚合、缩合、加热混配、恒温反应等工艺过程,对粘稠和颗粒的物质均能达到高搅拌的效果。

It is suitable for petroleum, chemical, pharmaceutical, metallurgical,scientific research, colleges and other departments to carry out high temperature and high pressure chemical reaction tests for hydrolysis,neutralization, crystallization, distillation, evaporation, storage, hydrogenation, alkylation, polymerization, condensation. The process of heating and mixing, constant temperature reaction, etc., can achieve high stirring effect on viscous and granular materials.

广泛应用于电镀产业园、化工厂、光伏厂、冶炼厂、市政污水处理厂、制药厂等各行各业,把高效传动搅拌的知识和水利及流态经验创新结合起来,让处理的每个工段和每一滴液体实现较佳的运行性能,致力于为客户创造更大价值而不懈努力!

咨询热线 0510-88550044

手机号码: 15995260980

公司QQ: 648935210

公司邮箱:liutao@jsshuangyue.com

公司地址: 江苏无锡市新吴区梅村新锦路110号

全国服务热线

全国服务热线